Food Manufacturing Lab Management Software

Food & Beverage Labs: Fast-Paced, Resource-Heavy, and Operationally Complex

Food and beverage labs must balance high throughput with strict process control across formulation, quality testing, and product release. Yet many still rely on disconnected spreadsheets, manual bookings, and siloed systems—slowing progress and increasing operational friction.

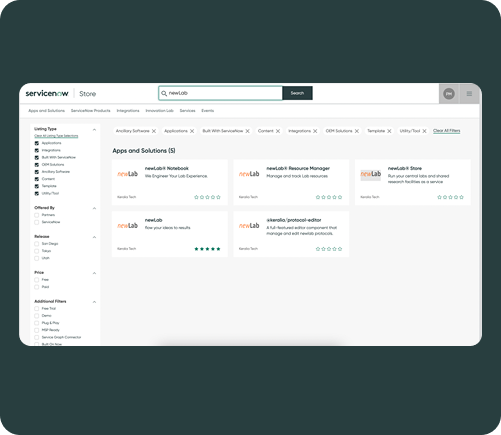

newLab® provides a centralized platform to manage lab scheduling, equipment tracking, and service requests—helping labs reduce delays, increase utilization, and move faster from development to delivery.

Use Cases for Food & Beverage R&D and QA Labs

Reducing Equipment Downtime Across Global Lab Sites

In multi-site pharma environments, equipment servicing schedules are often tracked manually or in disconnected spreadsheets—leading to missed calibrations, unplanned downtime, and costly delays.

How newLab® helps:

Automated maintenance and calibration workflows ensure every asset stays operational. Notifications, service logs, and availability updates are all centralized in one platform, so lab managers never miss a critical service window again.

Avoiding Redundant Purchases and Overspending on Capital Equipment

Procurement teams in biotech often lack accurate utilization data across departments or regions—resulting in unnecessary equipment purchases, overlapping functionality, or idle assets.

How newLab® helps:

With unified asset tracking and real-time usage analytics, newLab® helps organizations identify underutilized instruments, rebalance across sites, and prevent duplicate investments—supporting better budgeting and procurement alignment.

Eliminating Data Silos Between LIMS, ERP, and ServiceNow

IT teams often struggle with fragmented platforms that don’t “talk” to one another. This leads to duplicate data entry, inconsistent reporting, and slow access to key operational metrics.

How newLab® helps:

newLab® acts as a central orchestration layer—integrating natively with ServiceNow and via APIs with LIMS, ELN, and ERP systems. The result is a single, accurate source of truth for equipment status, usage, service history, and financial data.

Improving Lab Resource Access for Scientists Working on Critical Projects

Scientists lose valuable time due to unavailable or double-booked instruments, lack of visibility into equipment readiness, or delays in internal service fulfillment (like imaging or analysis).

How newLab® helps:

A self-service portal gives scientists the ability to view real-time equipment availability, make bookings, and track service requests. This accelerates experiment cycles and removes unnecessary administrative back-and-forth.

Scaling Lab Infrastructure During Rapid Growth or M&A

Fast-growing biotech firms or newly merged pharma divisions often inherit multiple lab systems and inconsistent operational processes, making it hard to scale efficiently.

How newLab® helps:

With configurable workflows and enterprise-grade scalability, newLab® brings standardization across global R&D operations—while still allowing teams to maintain autonomy at the site level. Labs get the structure they need without losing flexibility.

Keeping Instruments Ready Across Formulation and QA Labs

Instrument outages disrupt development and testing timelines, yet many labs rely on disconnected logs or manual reminders.

How newLab® helps

Automated maintenance and calibration workflows help ensure equipment stays operational. Lab staff can check statuses and plan ahead—avoiding unnecessary downtime.

Reducing Redundant Purchases and Idle Equipment

When teams lack visibility into what’s available or in use, costly duplicate purchases are common.

How newLab® helps

Real-time asset tracking and usage data across all locations make it easier to share resources and make informed procurement decisions.

Connecting R&D, QA, and Operations Teams

Disjointed workflows between departments can slow approvals, testing requests, and daily coordination.

How newLab® helps

Service requests, usage logs, and bookings all run through a centralized portal—giving all teams access to the data they need to stay aligned.

Giving Technicians Clear Access to Resources

Technicians and researchers often waste time navigating conflicting schedules or unavailable equipment.

How newLab® helps

A self-service portal gives each user real-time visibility into bookings, availability, and status—cutting down on bottlenecks and delays.

Scaling Operations Across Plants or Brands

As production expands or new brands are added, labs face more complexity and fragmentation.

How newLab® helps

The platform delivers global consistency while allowing local control—standardizing infrastructure without rigid workflows.

Key Capabilities for Food & Beverage Labs

Lab Equipment & Resource Management

Track every instrument by model, status, cost center, and location—ideal for shared labs and multi-plant environments.

Predictive Maintenance & Calibration Tracking

Reduce unexpected downtime with automated service workflows and scheduled maintenance alerts.

Scientific Service Request Automation

Accelerate lab support tasks like micro testing, sample prep, or formulation reviews with a built-in request system.

Multi-Site Lab Scheduling & Booking

Avoid conflicts with role-based booking calendars that simplify resource management across labs.

Enterprise-Grade Integrations

Integrates with ServiceNow, LIMS, QMS, and ERP systems to centralize your digital lab infrastructure.

Role-Based Access Control

Control what each user can see or do—ensuring security and clarity for technicians, R&D, QA, and IT.

Modernize Your Food & Beverage Lab Operations

Empower your lab teams to move faster, reduce waste, and stay coordinated—no matter how complex your operations become. From test scheduling to resource tracking, newLab® helps streamline every workflow in your lab ecosystem.